The Czech Republic is at the forefront of 3D printing technology. It’s known for its high level of skill and innovation. Businesses offer tailor-made prototyping that meets various industrial needs, from complex designs to mass production. They use top-notch 3D printing technology. This ensures accuracy, flexibility, and speed, marking Czech Republic’s leadership in manufacturing excellence.

Key Takeaways

- The Czech Republic is a global leader in expert 3D printing services.

- Companies offer bespoke prototyping solutions for diverse industrial needs.

- Advanced 3D print technology is utilised for high precision and efficiency.

- Czech 3D printing expertise ensures adaptability and innovation in manufacturing.

- Local providers are renowned for aligning with global quality standards.

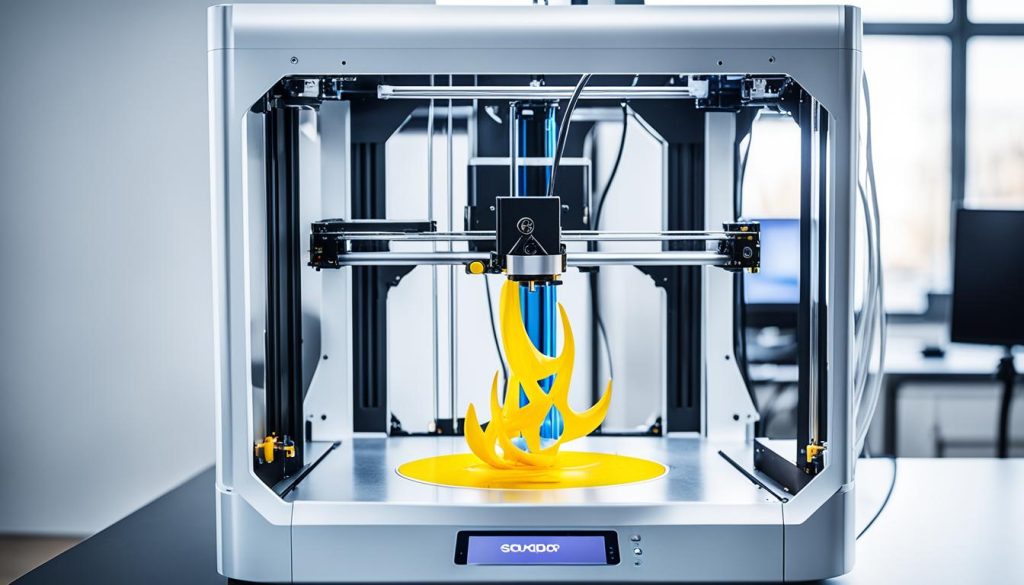

Introduction to 3D Printing Technology

3D printing technology has changed the way we make things. Known also as additive manufacturing, it lets us create 3D objects by adding material layer by layer. This method is guided by computers, offering lots of design freedom and better efficiency.

What is 3D Printing?

3D printing turns digital designs into real objects by adding materials a layer at a time. It uses different materials, including plastics, metals, and composites. This makes it possible to create shapes and details that are hard or impossible to make with old methods. 3D print applications are varied, from making models to building parts for many industries.

History of 3D Printing

The story of 3D printing began in the 1980s with Charles Hull’s invention of stereolithography. Since then, the evolution of 3D printing has brought major changes, making it a key part of modern manufacturing. From its first patent to new printing techniques, its development is truly impressive.

Applications of 3D Printing

3D printing is changing many sectors in big ways. The aerospace field uses it for parts that are strong but light. The car industry uses it for fast prototyping and making special parts. In healthcare, it helps make personalised prosthetics, implants, and even body tissues. It’s also used by companies making consumer goods for custom products. This shows how broad and game-changing 3D print applications are.

The Growth of 3D Printing in Czech Republic

In recent years, the Czech Republic has seen significant advances in additive manufacturing. This highlights the strong Czech additive manufacturing growth. Industries like aerospace, automotive, electronics, and healthcare are leading the way. They are incorporating sophisticated 3D printing methods into their operations.

The 3D printing market development is evolving, with many sectors embracing this technology’s potential. The need for customized and quickly produced components is increasing. This opens up exciting possibilities in various fields.

Key Industries Adopting 3D Printing

Several sectors in the Czech Republic are turning to 3D printing. They seek accuracy, efficiency, and innovation.

- Aerospace: Uses 3D printing for prototyping and making complex parts. This boosts performance and cuts down on weight.

- Automotive: Applies additive manufacturing for creating custom parts, prototypes, and special tools.

- Healthcare: Moves forward with personalized medical devices, implants, and prosthetics. It uses precise 3D printing.

- Electronics: Innovates with printed circuit boards (PCBs) and bespoke electronic components for new designs.

Market Trends and Insights

An in-depth look at the 3D printing market development shows several key trends and insights. The Czech Republic’s 3D printing sector is witnessing:

- Increased Customisation: Firms are putting more into 3D printing to provide highly tailored and bespoke products. This improves customer happiness.

- Reduced Lead Times: Using this tech has drastically reduced the time-to-market for products. It leads to quicker innovation.

- Consumer Goods Revolution: Electronics and consumer goods makers are quickly adopting 3D printing. This makes production smoother and invites new design trials.

These points highlight the Czech Republic’s emerging role as a centre for 3D printing. It shows the strong Czech additive manufacturing growth and lively 3D printing market development.

Benefits of Using 3D Printing Services

Using 3D printing services offers a lot of benefits for businesses wanting to innovate and improve their processes. Here are some of the main advantages:

Cost-Effectiveness

One of the biggest benefits is how it saves money. 3D printing cuts down on waste and the need for large storage spaces. This means companies can save on costs. Plus, making custom 3D parts does not require expensive moulds or tools. This makes the whole production process cheaper.

Speed and Efficiency

Speed is another huge benefit of 3D printing. Unlike traditional methods, 3D printing can quickly make prototype models in just hours. This is great for companies wanting to speed up their research and development. It helps get products to the market much faster.

Customisation and Flexibility

The ability to customise and adapt with 3D printing is unmatched. Companies can make complex and tailored parts that fit exact needs. Changing designs fast without extra costs is another big plus. This flexibility is something traditional manufacturing can’t match.

Types of 3D Printing Technologies Available

3D printing has various amazing technologies tailored for different needs and uses. Let’s explore three main types: Stereolithography (SLA), Fused Deposition Modelling (FDM), and Selective Laser Sintering (SLS).

Stereolithography (SLA)

SLA printing is famous for its high-precision and smooth parts. It uses a photopolymer resin that a UV laser cures. SLA is ideal for complex designs needing fine details. It’s top for models with a great surface look and needed in industries where accuracy is key.

Fused Deposition Modelling (FDM)

FDM technology is known for being versatile and affordable. It builds objects layer by layer with thermoplastic materials. It’s great for making strong and functional parts. Many industries like FDM for prototypes and final products that must last.

Selective Laser Sintering (SLS)

The SLS 3D print methods make durable and complex shapes without support structures. It uses a laser to turn powdered nylon into solid objects. SLS is vital for making strong, light parts and items that fit perfectly. It’s a top choice in aerospace, cars, and healthcare.

Choosing the Right 3D Printing Service Provider

Choosing the right 3D print service requires careful thought. You need to look at many important points. Doing this helps you make wise choices and get the results you want.

Factors to Consider

Several key factors need careful consideration when choosing a 3D printing service:

- Technology Options: Check what types of technology they offer, like SLA, FDM, or SLS.

- Materials Expertise: Make sure they know about different materials and can meet your project’s needs.

- Turnaround Times: It’s important to know how long they take to deliver, to meet your deadlines.

- Cost Structures: Understanding their pricing helps manage your budget effectively.

- Quality: The quality must be good. Look at their samples and how they control quality.

Comparing Service Providers

Comparing different 3D printing services is crucial. You should look at their skills, past work, and what customers say about them. Here’s how to compare them:

| Criteria | Provider A | Provider B | Provider C |

|---|---|---|---|

| Technology Options | SLA, FDM | FDM, SLS | SLA, SLS |

| Materials Expertise | Plastics, Metals | Plastics, Composites | Metals, Composites |

| Turnaround Times | 5-7 Days | 3-5 Days | 7-10 Days |

| Cost Structures | Moderate | Flexible | High-End |

| Quality | High | Medium | High |

| Customer Feedback | Positive | Mixed | Positive |

Focusing on these points makes choosing the right 3D printing service easier and more effective.

Advantages of Local 3D Printing Services in Czech Republic

Local 3D printing services in the Czech Republic make the production process smoother. One key benefit is fewer shipping times and costs. This means businesses can get their prototypes or final products faster. It speeds up the project timeline and boosts efficiency.

Enhanced communication with service teams is another vital benefit. Working with local providers allows for better and more regular talks. This ensures the final product meets the client’s needs perfectly. Such teamwork leads to prototypes that fit exactly what the client wants.

Choosing local services helps the local economy grow. It supports the industry’s growth and sustainability. This choice helps spur more innovation and development in the 3D printing field and other areas.

In the Czech Republic, local providers know the market well. They can adjust their services to meet specific demands. Whether it’s fast prototyping, custom production, or unique materials, local know-how delivers practical and inventive solutions.

Choosing local 3D printing services in the Czech Republic has many benefits. It not only improves the efficiency of prototyping and production. It also ensures outcomes that meet high-quality standards and support the local economy.

Case Studies of Successful 3D Printing Projects

Looking at successful 3D printing projects helps us see how this technology changes things. It has reshaped manufacturing and product design in many industries.

Automotive Industry

In the car industry, 3D printing has led to some great achievements. It lets car makers build complex automotive prototypes quickly. This process results in-parts that make cars lighter, go faster, and use less fuel.

Medical Devices

3D printing is also changing healthcare in big ways. It’s used for medical 3D print applications like custom implants and models for surgery. These breakthroughs help doctors prepare better and improve patient results.

Consumer Products

The consumer goods sector now offers more custom options thanks to 3D printing. Brands can quickly make products tailored to what customers want. This has made product development quicker and offerings more unique. These stories from different fields show how 3D printing is truly innovative and flexible.

Material Options for 3D Printing

The type of material chosen for 3D printing greatly influences the final product’s traits and uses. With options like plastic, metal, and innovative composites, the variety available is vast. This allows for everything from detailed plastic models to strong metal parts.

Plastics

Plastics lead in 3D printing for being adaptable and budget-friendly. They are often used for making plastic prototypes. Materials such as PLA, ABS, and PETG are popular for their mix of strength, flexibility, and user-friendliness. Plastics make it easier to craft detailed and functional prototypes very precisely.

Metals

Metal 3D printing has transformed areas like aerospace, car making, and healthcare. Metals, including titanium, aluminium, and stainless steel, are sought after for their toughness, heat resistance, and longevity. These metal creations stand out for their detailed complexity. This is something hard to get with traditional methods.

Composites

Composites in 3D printing are on the rise. They merge different materials’ qualities into a single, hybrid product. This results in items that are both light and strong. Fields that require ultimate performance and reliability often turn to composites. Carbon fibre-reinforced polymer is prized for its strength while being light.

To sum up, the 3D printing world is rich with material choices, including plastics, metals, and composites. This offers an array of innovative possibilities across numerous fields. Every material type serves a different purpose, helping makers pick what’s best for their projects.

Future Trends in 3D Printing Services

The future of 3D printing services is quickly changing. This is because of big steps forward in technology. As the industry grows, improving printer speed, size, and accuracy is key.

Technological Advancements

One key trend for 3D printing is the huge improvements in printer technology. Latest models are now faster and can create bigger items. They also make very detailed items more accurately. Besides, better software and control systems make printing more efficient and easy to use.

Innovations in Materials

New materials are also changing the future of 3D printing. Developers are creating new 3D materials like better polymers, safe-for-health substances, and strong alloys. These materials are making products that last longer, work better, and have more uses.

Integration with Other Technologies

Mixing 3D printing with other cutting-edge technologies, like AI and IoT, is a game-changer for manufacturing. By using AI and IoT, 3D printers can join a smart manufacturing system. This makes making things more precise and efficient. It also makes 3D printing more valuable in different fields.

| Future 3D Printing Trends | Benefits |

|---|---|

| Enhanced Printer Technology | Faster, larger, and more accurate prints |

| Innovative 3D Materials | Expanded capabilities for diverse applications |

| Technology Integration | Smarter and more efficient manufacturing processes |

The Environmental Impact of 3D Printing

3D printing has both positive and negative effects on the environment. Technology is moving towards greener practices. This aims to lessen the harm done to our planet.

Sustainability in 3D Printing

To be more sustainable, 3D printing focuses on cutting down waste and using less energy. Efforts include making printing processes use fewer materials and be more energy-efficient. Using clean energy sources in 3D print shops also helps the environment.

Eco-Friendly Materials

Using eco-friendly materials is key to greener 3D printing. These include plastics that degrade naturally and metals that can be reused. Creating these better options is critical for lessening the environmental damage.

| Aspect | Description |

|---|---|

| Sustainable 3D Printing Practices | Efforts to minimise waste and energy consumption during the 3D printing process. Utilising renewable energy sources optimises environmental impact. |

| Eco-Friendly 3D Print Materials | Includes biodegradable plastics and recycled metal powders which are vital in reducing carbon footprints. Biodegradable plastics, like PLA, break down naturally, and recycled metal powders can be reused in production cycles. |

Yet, some 3D printing methods use a lot of energy, and post-processing can cancel out the green efforts. It’s vital to keep these issues in balance to make 3D printing truly sustainable for the future.

3D Printing in Education and Research in Czech Republic

3D printing is changing learning and research in Czech schools. Universities add it to their courses. This prepares students for new jobs and encourages fresh ideas.

Academic Institutions Adopting 3D Printing

Czech schools are quickly adopting 3D printing. Charles University and Czech Technical University in Prague lead by example. They mix classic engineering lessons with 3D printing, making students ready for today’s workforce.

Research Projects and Grants

There’s big support for 3D printing research in Czech. It includes work in bioprinting and new materials. These efforts improve science and strengthen school-industry ties, boosting 3D print uses.

| Institution | Key Focus Area | Recent Projects |

|---|---|---|

| Charles University | Bioprinting | 3D Printed Tissue Structures |

| Czech Technical University | Material Development | New Composite Materials for Additive Manufacturing |

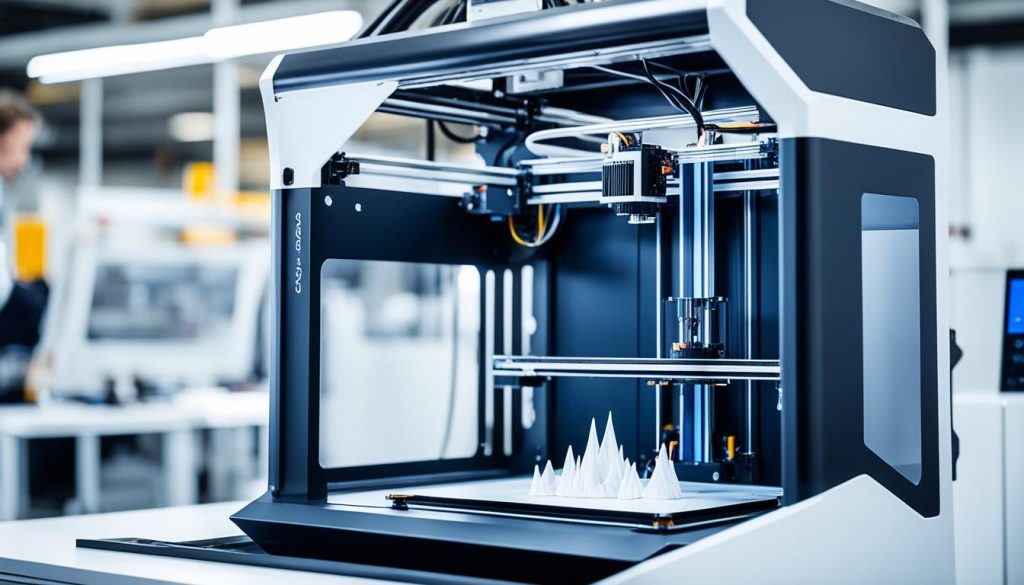

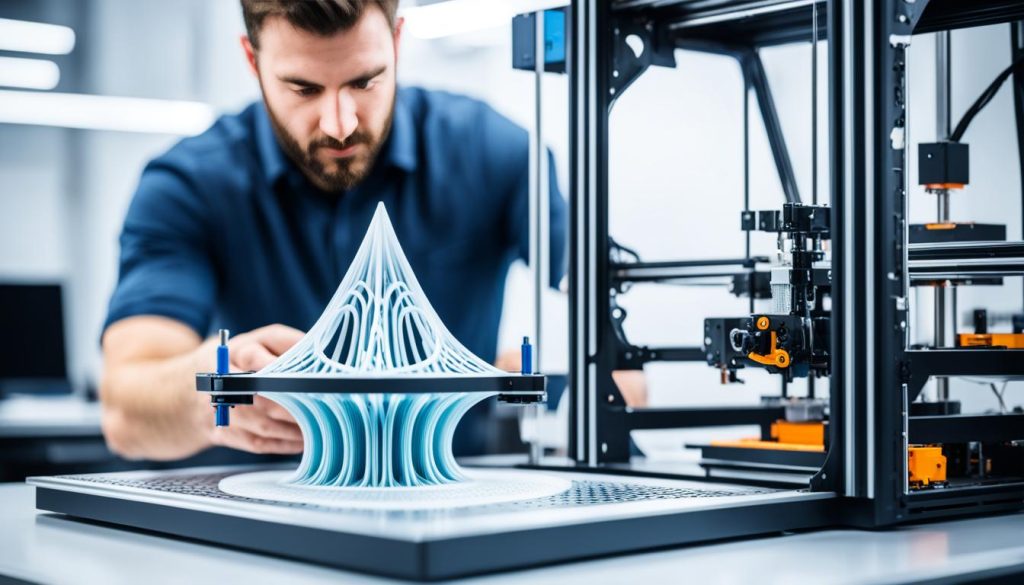

3D Printing for Prototyping and Production

3D printing is a key tool for both prototyping and mass production. It lets designers and engineers quickly try out ideas. They can test and improve their designs much faster than before. On the production front, 3D printing means items can be made on-demand. This cuts down on storage costs and makes it easier to create custom products. As 3D printers get better, they’re being used more for large-scale manufacturing.

Rapid Prototyping Benefits

3D rapid prototyping has changed how products are designed and developed. Designers can make many versions of a design very quickly. This speeds up the whole process, getting products to market faster. Also, 3D printing can make shapes that are too complex for usual methods. This lets companies be more creative and break new ground.

Scale Production Solutions

In large-scale 3D production, the benefits stand out. Companies can make items only when they’re needed, avoiding big stockpiles. This saves space and money and allows for more bespoke products. Also, new materials mean 3D printed parts are both strong and look good. This supports more eco-friendly manufacturing, meeting today’s environmental goals.

Digital Design and 3D Printing

Digital design turns ideas into real objects through 3D printing. It uses 3D print design software and CAD for 3D printing. These tools help designers make detailed and accurate models perfect for additive manufacturing.

Software Tools

Software is key in digital manufacturing. Top 3D print design software like AutoCAD, SolidWorks, and Fusion 360 are vital. They help in designing complex shapes and running simulations. This ensures designs are ready for 3D printing.

Design Considerations

Designing for 3D printing requires special care. You must consider the technology’s limits and benefits. This includes thinking about support structures, how the layer resolution affects looks, and handling parts that stick out. Knowing these helps make the design better and usable in the real world.

Challenges in 3D Printing Adoption

3D printing is growing but faces barriers. These range from technical to economic and regulatory challenges.

Technical Challenges

Quality and durability in 3D prints are big concerns. Advances have been made, but prints still vary in strength. Research is underway to improve this. However, keeping high standards is tricky.

Also, 3D printers need a lot of upkeep. They require frequent maintenance and calibration, hindering their widespread use.

Economic Barriers

The cost of 3D printing technology is high. This makes it tough for small and medium businesses to start using it. The price of equipment, materials, and training adds up. Also, maintenance and material costs keep growing, posing financial challenges.

Regulatory and Compliance Issues

In industries like aerospace and healthcare, meeting regulatory standards is a must. These rules ensure safety and reliability but can slow innovation. The process of getting approval involves lots of testing. Navigating these standards is essential but can be complex.

| Challenge | Description |

|---|---|

| Technical Challenges | Precision and strength of prints, maintenance, and calibration issues. |

| Economic Barriers | High initial investment, ongoing costs of materials and maintenance. |

| Regulatory and Compliance Issues | Strict adherence to standards in aerospace and healthcare industries. |

Conclusion: Innovation through 3D Printing Services

3D printing services in the Czech Republic are transforming traditional manufacturing. They focus on innovation and use future-proof techniques. These changes help Czech businesses change how products are made.

The custom solutions from additive manufacturing make products faster, cheaper, and more efficiently. This new way of making things is not without its challenges, though. Companies face technical issues, economic factors, and rules they must follow. But technology and science keep improving, giving 3D printing the power to revolutionize industries.

Various sectors in the Czech Republic are working together. They aim to overcome these challenges and make the most of 3D printing. This cooperation shows their commitment to the future of manufacturing.

The role of 3D printing in mainstream manufacturing is growing. This positions the Czech Republic as an important global player. By embracing innovation and adaptability, the country is set to lead in advanced manufacturing. This opens up new possibilities for growth and development.